Many workshops rely on CNC machining as the backbone of their production processes. However, with the rise of additive manufacturing, more and more companies think about including 3D printing into the workflow or even replacing their CNC machines. Let us give you an overview of what 3D printing can do for you, and how you can best combine both processes.

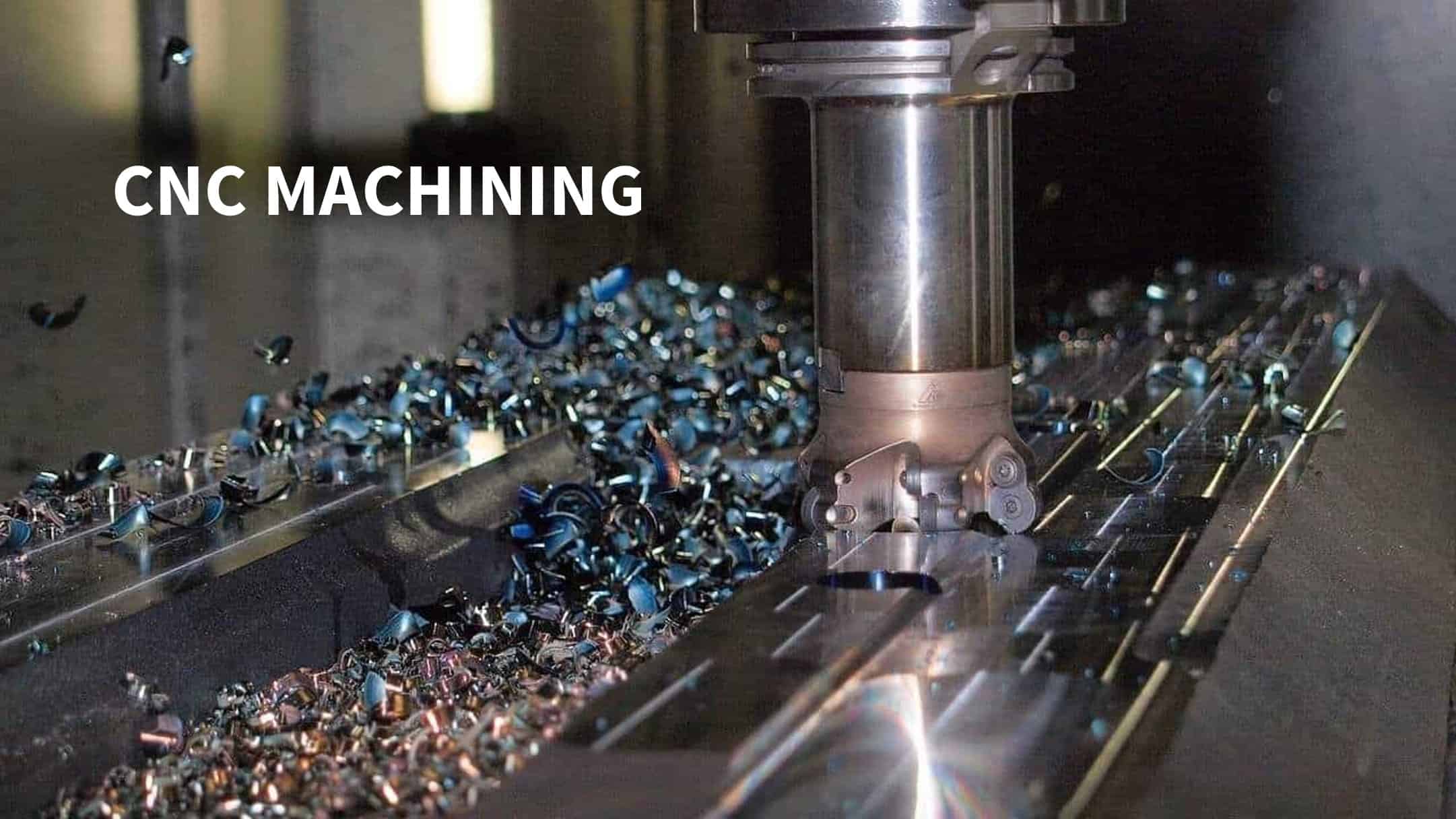

Overview of CNC machining or Subtractive Manufacturing

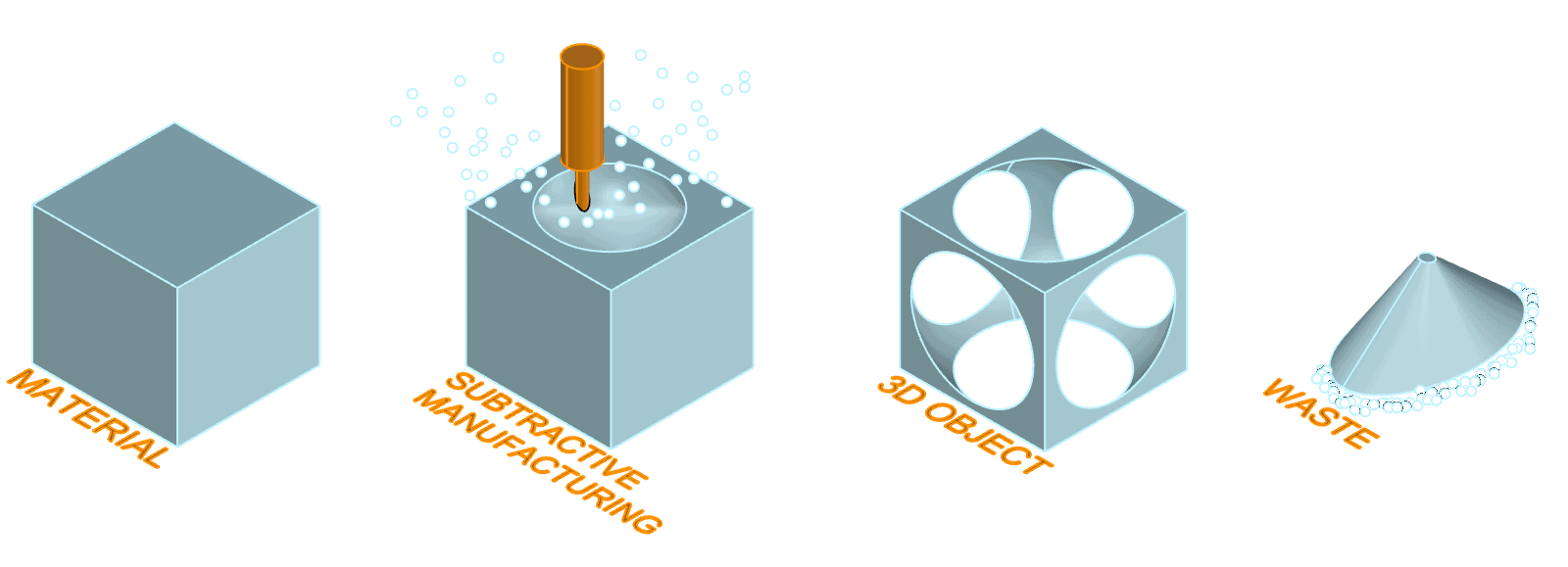

CNC machining uses a computerized tool machine to produce the desired object by removing the surplus material from a blank. It is still the most cost-effective process for manufacturing parts in medium to large numbers. As a tried and tested method, CNC machines are available in workshops all over the world, and extensive knowledge exists about the whole process chain. It is very versatile in terms of materials that can be machined, geometries that can be produced, and achievable surface qualities and tolerances. Therefore, in many cases, CNC machining is still the method of choice.

However, CNC machining is still a highly specialized process, especially if geometries are of higher complexity or challenging materials are involved. CNC machining also requires highly skilled designers and programmers, leading to high personnel costs. Often special clamping tools are required, which must be designed and manufactured as well. This increases part costs, even more so, if the parts are in small numbers. Also, since you are starting with a block of material when CNCing a part, material cost will always be higher, and the amount of waste will also be more.

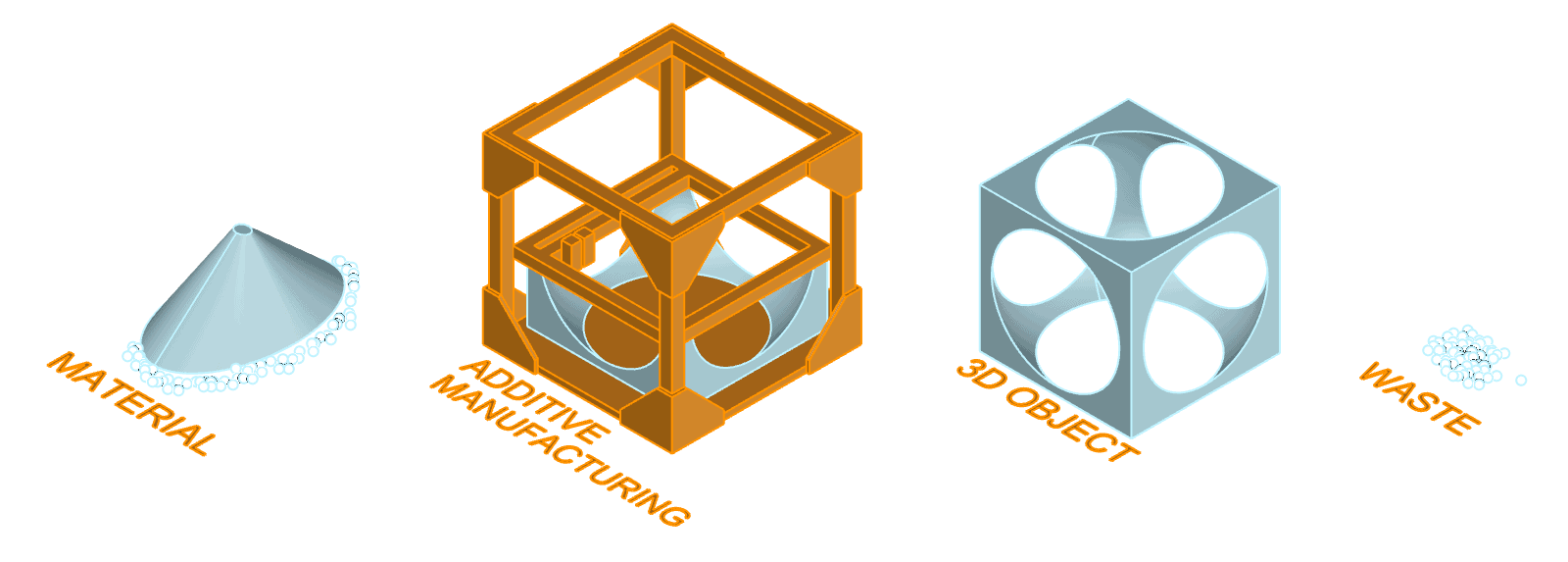

Overview of 3D Printing or Additive Manufacturing

Although various methods of 3D printing have proven to be a viable manufacturing process, it still is not as common as conventional machining. But FFF (Fused Filament Fabrication) is becoming more and more popular in various industrial branches to produce small to medium batches of end-use parts or prototypes. Plastic is melted, then extruded through a nozzle, and the part is built up layer by layer. Apart from support structures, only the amount of material making up the final part is used, so almost no waste is produced. The object is printed directly on the flat surface of the print bed, so no clamping tools are required. Only a little specific knowledge is required to set up a BigRep printer and start a print. The printing process itself does not limit the part design in any way; almost any geometry can be printed. This helps in overcoming established ways of thinking in design and development. Riley Gillman, Technical Operations Manager at Nikola Motor Company said, "You can really challenge the engineering process and the manufacturing process!”

Due to the layer-based process, the surface quality is not comparable to milled parts and can require post-processing to a certain extent. And although more and more parts with very narrow tolerances can be printed, values as they are common for milled parts often cannot be matched. The choice of material is also limited; FFF only allows plastics to be used that can be melted.

How to Use Your Big 3D Printer Best?

Hand Jigs and Production Tools

This handheld tool that is used during the assembly of cars shows one typical application. The over 120 cm long part was initially planned to be milled out of a block of aluminum. However, overall costs, including machine, personnel, and material costs would have been around 10.000 € with an estimated time to completion of about two weeks. A Chinese manufacturer quoted 5.800 USD with a similar delivery time. Finally, it was decided to print the part in BigRep HI-TEMP CF on a BigRep PRO, which took 32 hours. The costs were about 790 USD, resulting in savings of 86%! A welcome side effect for the users handling the part was a reduction in weight of about 50%, compared to the aluminum version. All things considered, a very successful use case.

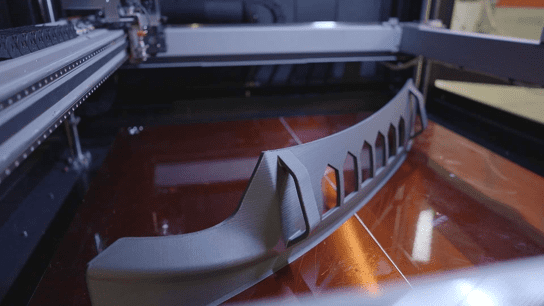

3D Printed End-Use Parts

Boyce Technologies uses 3D printing to produce end-use parts in their 5G kiosks that they make for Verizon. Due to the special shape of these air ducts, milling would have taken a long time and required extensive preparation time and post-processing. By 3D printing the parts instead, huge costs were saved in not only time and material costs, but also with the number of employees required to support preparation and post-processing. With large-format additive manufacturing, another benefit is that many parts can be printed at the same time, allowing for optimal use of the printer’s build volume.

How to Combine 3D Printing and CNC Machining?

The advantages additive manufacturing offers can be increased even more by combining it with other manufacturing processes. 3D printed objects can be reinforced by metal parts in places where higher loads occur; insert nuts made of brass can be inserted in plastic parts. Printed parts can also be machined in order to achieve dimensions with critical tolerances or required surface qualities, or even to mill threads. Jigs and fixtures as well as clamping and positioning tools made by 3D printing facilitate working with CNC machines. By intelligently combining 3D printing and CNC machining, users can benefit from the advantages of both processes.

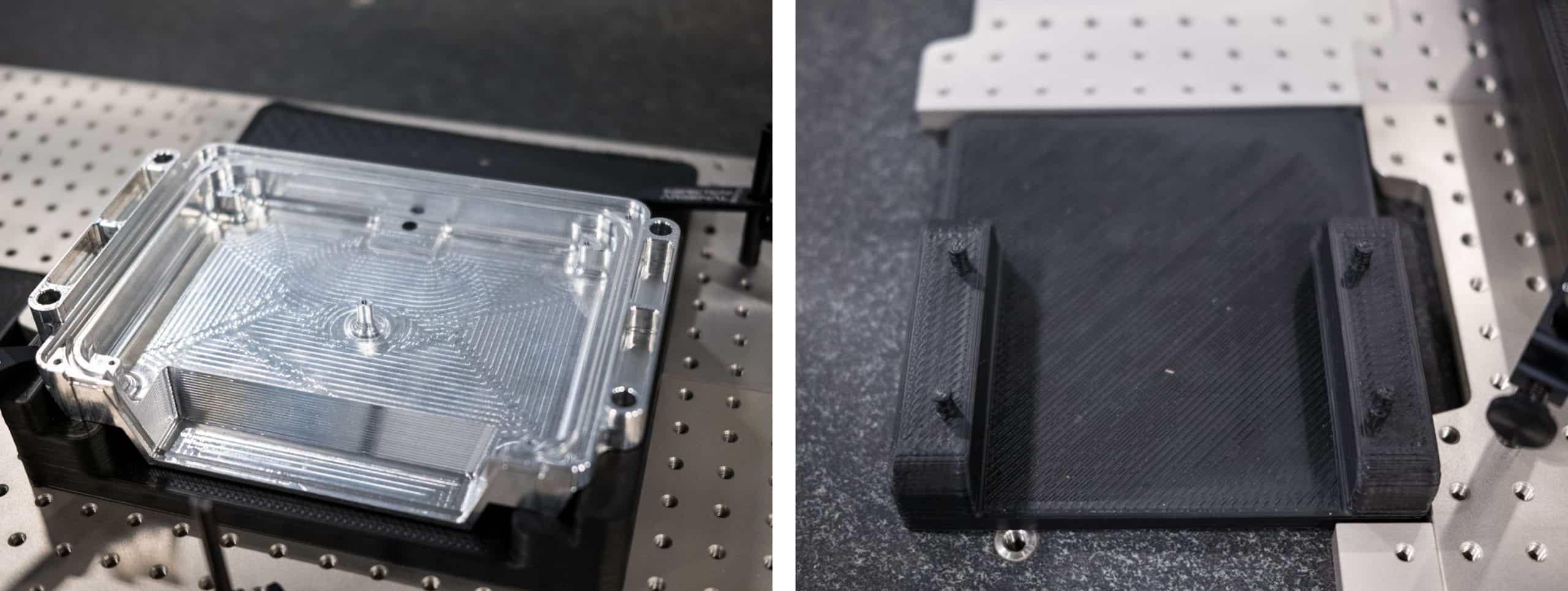

A perfect example of how the 3D printer is also helpful when designing and manufacturing simple jigs, like positioning or assembly tools, as shown below. In this application, Gillman at Nikola was tasked to find a way to securely hold an aluminum part in place for CMM inspection. The aluminum part itself could not have been produced by 3D printing due to very specific geometrical requirements, so it had to be milled on a CNC machine. But making the fixture from aluminum would have required open space on a CNC machine and a lot of raw material. So, Gillman decided to produce it using his BigRep PRO. From idea to part, it only took a few hours, at material costs of under 20 USD!

In the last few years, Nikola Motor Company has experienced an increased shortage of materials as an ever-decreasing availability of external suppliers. Here a 3D printer offers flexibility and independence.

Riley Gillman summarizes the reasons for using his 3D printer: “Very often, we produce large parts with very challenging time limits. The geometry of the parts plays a large role; some of the parts are simply too complex to manufacture them using conventional methods. And sometimes we simply don’t have the budget to use any other process than 3D printing!”

How Can You Profit from Additive Manufacturing?

3D printing is most commonly used when large parts are required on short notice or when multiple iterations of a single part are needed. 3D printing enables you to make changes to 3D models quickly and easily, and then manufacture them in-house, massively reducing lead times. Functional prototypes are available much faster and you have a better idea of what the final product will look like.

Is it Beneficial for You to Use 3D Printing?

It is important for companies to understand the costs behind a 3D printer and what the ROI will look like. Here is a simple example: If you are paying about 5.000 USD per part with a 3D printing service and you need 4 similar sized parts per month, you will be spending about 20.000 USD a month! When you start comparing this to what it costs to purchase a printer, it becomes apparent that buying a printer is a worthwhile investment.

Which Process is Best Suited for You?

After all these considerations, the answer “It depends!” is easier to understand. The first step should always be, deciding which technology is best for your part and its intended use. Both processes have their advantages and their own applications, so 3D printing will not fully replace CNC machining.

And if you aim to combine both processes so that they complement each other, buying a 3D printer will give you many benefits, including:

- increased flexibility and independence

- time and costs savings

- expanded manufacturing portfolio

- improved internal processes

If this sounds interesting to you, speak to one of our experts! We will show you which one of our 3D printers is best suited for you and your applications. Or send us a CAD file of a sample part, and we will calculate costs and printing time for you.

Thanks for checking out the EXBuild blog! For more information about how you can get started with additive manufacturing at your business, contact us today.

Written by BigRep

BigRep develops the world’s largest serial production 3D printers, creating the industry benchmark for large-format additive manufacturing. Our award-winning, German-engineered machines are establishing new standards in speed, reliability and efficiency.