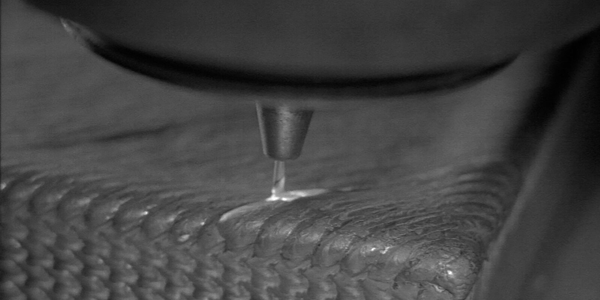

This case study presents the internal evaluation of manufacturing a 150 mm diameter Adapter Plate for the Inert Bubble using Metal Additive Manufacturing with Meltio technology. The analysis compares three approaches: in-house production (Meltio LMD + partial machining), traditional full in-house machining, and outsourcing to a third-party supplier.