The new Meltio M600 is designed to solve problems of long lead times, costly stock-keeping and increasingly fragile supply chains, thanks to its unique metal 3D printing technology. This new system increases productivity and reduces manufacturing costs, brings new materials to the table and most importantly is ready to perform 24/7 with minimal operator interaction for autonomous production.

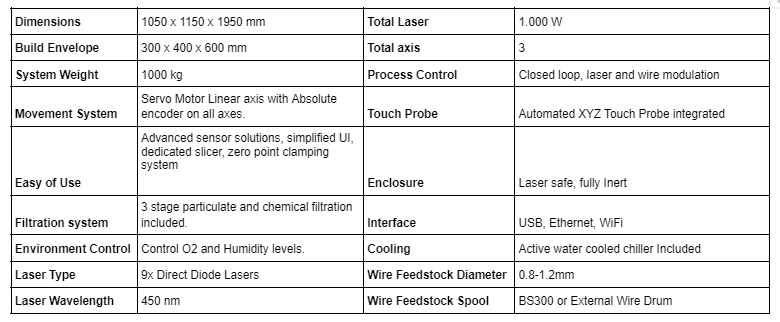

To make this new tool for machine shop use a reality, the Meltio M600 is the first Industrial wire-laser metal 3D printer that incorporates, among other technological advances, a Blue Laser deposition head. These lasers improve energy absorption and printing efficiency across the metal spectrum and open up new material possibilities while reducing the carbon footprint for production.

The Meltio engineers have also managed to improve the energy distribution and wire guidance such that the deposition head is aligned from the factory and not operator-adjustable leading to consistent output and vastly reduced maintenance. Lastly, the head is laden with new and improved sensor solutions for monitoring the printing process, which makes printing more reliable.

Key Features

- It uses welding wire as its feedstock compared to the much more common powder-based 3D printer. Having a wire material that is much cheaper, safe to handle and that does not risk contamination of your CNC Machines is a huge advantage for industrial integration.

- Printing Parts with our Wire-Laser Deposition process also produces high-quality components with material properties that are comparable to conventionally manufactured parts.

- Our newly developed Blue Laser deposition head increases printing speed while reducing energy consumption thanks to the increased absorption of the short wavelength light compared to most industrial lasers which emit near-infrared light. This advantage is multiplied for reflective materials such as copper and aluminum alloys where near-infrared lasers lead to unsatisfactory results. Combining this with the fully inert workspace, the Meltio M600 can process a large range of materials efficiently while producing parts with exceptional properties.

- The complete system has been designed to easily interface in the same industrial environment with CNC machines, it features a built-in 3-axis touch probe and supports various types of work holding solutions which means you can also add features to or repair existing parts rather than printing them entirely.

- Lastly, the Meltio M600 is highly autonomous meaning that operator interaction is minimal, common touch points such as manual laser alignment have been removed for increased reliability, and programming is a matter of minutes thanks to the Meltio Horizon, the dedicated slicer for the Meltio M600.

Applications

While the Meltio M600 is interesting to a broad range of sectors, the company’s goal was to design a system that fits right into any machine shop and works alongside CNC machines, creating value by reducing material waste, and lead times, allowing for increased manufacturing flexibility. To realize this vision our focus was a system that works like a machine tool, designed for lights-out manufacturing, and is easy to use, enabling existing operators to complete complex print jobs with minimal time investment.

These attributes make the Meltio M600 an exciting proposition for the manufacturing industry as a whole and get a lot of traction from a wide range of sectors: automotive, aerospace, oil & gas, mining, and defense.

Written by The EXBuild Team

The EXBuild Team of application engineers combined their depth of experience and industry knowledge to bring you the contents of this article.