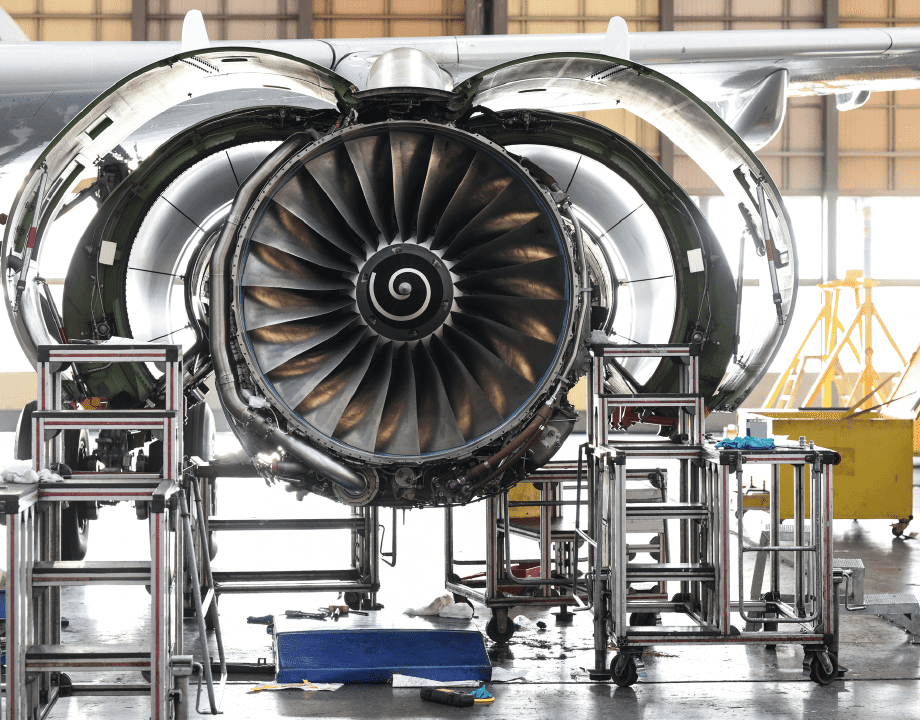

Built to be the ultimate machine on the production floor, the ALTRA 280 is the answer for the most demanding applications for industries ranging from aerospace, military, and defense to automotive. It features top-of-the-line specs such as a fully enclosed high-temperature printing environment, up to four state-of-the-art DSX extruders, an open material system compatible with BigRep and third-party filaments, and a massive build volume making it a mighty production beast.

An Industrial Powerhouse from HAGE3D

HAGE3D, a company specializing in large-format high-temperature machines that are part of BigRep through a planned acquisition, originally built the ALTRA 280. The machine is well-known in the European region formerly as PRECISE. The planned acquisition extends our portfolio by offering a full spectrum of low-to-high-temperature 3D printers on a large-scale platform.

Reinventing Industrial Workflows

Whether you're looking to build aerospace-grade parts, iterate functional prototypes, or produce robust tooling in-house, the ALTRA 280 offers unmatched precision, automation, speed, and versatility to take your factory floor to the next level.

1. Aerospace-Grade Parts

Print safe and robust parts that qualify in the aerospace industry with the ALTRA 280. This advanced 3D printer uses high-performance materials to produce strong, lightweight, and functional parts. Its exceptional precision, repeatability, and resolution enable innovation at every stage of the design and production process.

2. Functional Prototypes

Test and validate designs before final production. The machine's open-material system allows you to choose from a wide variety of filaments, ensuring accurate replication of the final product. This flexibility accelerates iteration, reduces fabrication costs, and speeds up time-to-market.

3. Durable tooling

Create cost-effective, rapid tooling for your factory, including jigs and fixtures. The high-temperature capabilities enable the in-house production of strong and geometrically complex tools. Bypass traditional manufacturing constraints and print-on-demand tools efficiently.

An Open Material System to Print All Filaments

The ALTRA 280’s material system, like all BigRep machines, is open for innovation. This unlocks the flexibility to print with any compatible 3D print filament, whether BigRep’s or a third party’s, opening up new applications and possibilities.

The ALTRA 280 is fully compatible with BigRep’s filament portfolio including industrial-grade materials that cater to a range of needs, from cost-effective, general-use materials to specialized technical materials. These filaments are produced under carefully controlled conditions to ensure uniform diameter and consistent composition, guaranteeing reliable and even extrusion.

Compatible 3D Print Materials

PC (Polycarbonate)

Known for its high strength, impact resistance, & transparency, PC is ideal for robust, durable parts.

PC-ABS (Polycarbonate/acrylonitrile butadiene styrene)

Combines the strength & heat resistance of PC with the flexibility of ABS, predominantly used in automotive and electronic applications.

PC-FR (Flame Retardant Polycarbonate)

A flame-retardant variant of PC, perfect for applications that need to meet stringent fire safety standards

PC-CF (Polycarbonate reinforced with Carbon Fiber)

Polycarbonate reinforced with carbon fibers offer superior stiffness and strength.

PA6, PA12 (Nylon)

Both materials are known for their toughness, chemical resistance, and durability, they are excellent for mechanical parts and functional prototypes.

PA6-CF, PA12-CF (Polyamide Reinforced by Carbon Fiber)

Nylon with carbon fiber reinforcement, providing superior strength and light-weight parts.

PA12-GF (Polyamide Reinforced by Glass Fiber)

Nylon reinforced with glass fibers delivers superior stiffness and dimensional stability.

CoPA

A copolymer of nylon that combines the best properties of different nylons are perfect for a wide range of applications.

ABS (Acrylonitrile Butadiene Styrene)

A flame-retardant variant of PC, perfect for applications requiring stringent fire safety standards.

ASA (Acrylic Styrene Acrylonitrile)

Similar to ABS but with better UV resistance, ASA is great for outdoor applications.

ABS-FR

Flame-retardant ABS for applications that demand fire safety.

ABS-ESD

Electrostatic discharge-safe ABS is used in electronics and sensitive equipment housings.

TPU (Thermoplastic Polyurethane)

A flexible and durable filament for parts requiring elasticity.

TPC (Thermoplastic Copolyester)

Known for its flexibility and chemical resistance, TPC is best used for textiles, packaging, electronics, and automotive applications.

PETG (Polyethylene Terephthalate Glycol)

A durable, easy-to-print material with good chemical resistance.

PLA (Polylactic Acid)

A biodegradable, eco-friendly filament used for general-purpose printing.

HT-PETG (High-Temperature Polyethylene Glycol Terephthalate)

High-temperature PETG with enhanced heat resistance and durability.

PCTG (Poly Cyclohexylenedimethylene Terephthalate glycol-modified)

A modified version of PETG, offering improved impact and chemical resistance.

PP (Polypropylene)

Lightweight, flexible, and resistant to fatigue and chemicals, ideal for hinges and containers.

PP-GF

Polypropylene reinforced with glass fibers is known for superior strength and stiffness.

PEKK, PEEK (Polyether Ether Ketone)

High-performance materials guarantee exceptional mechanical properties and resistance to extreme temperatures and chemicals.

PPSU, PSU (Polysulfone)

High-performance thermoplastics with excellent chemical resistance and thermal stability.

PAEK (Polyaryletherketone)

Known for its mechanical strength and chemical resistance, it is suitable for high-stress applications.

PEI (ULTEM)

A high-performance polymer with excellent thermal, chemical, and flame resistance.

The Ultimate High-Temperature 3D Printer

The ALTRA 280 is a high-performance industrial beast with a large build volume, high-temperature capabilities, unlimited material options, and features that deliver reliable results with every print.

The machine is everything at once – a blazing hot, large, fast, reliable 3D printer manufacturing complex production-quality parts without compromise.

Written by BigRep

BigRep develops the world’s largest serial production 3D printers, creating the industry benchmark for large-format additive manufacturing. Our award-winning, German-engineered machines are establishing new standards in speed, reliability and efficiency.