The ability to additively manufacture near net shape parts has long been a holy grail of manufacturing. As a result, Metal 3D printing (the technology that seems likely to deliver on that promise), has carried an immense amount of “hype.” The blind excitement for the process largely overshadow the actual benefits of metal 3D printing, which paint the picture of a unique fabrication method that can specifically add value to the manufacturing process in a few key ways.

What are the benefits of 3D printing metal?

Cost per part is consistent at low and high volumes

Complex parts are not more difficult to 3D print than simple parts.

Metal 3D printing can create parts that are impossible to make with any other fabrication method.

Metal 3D printing cost per part is the same at low and high volumes

Almost every fabrication method in existence gets cheaper on a cost/per/part basis with increased volume. Casting, machining, and forming (among others) are perfect examples of this. At low and medium volumes, they can be prohibitively expensive to implement. However, at large scale they are far and away the cheapest way to fabricate a part. This is due to the difference between overhead costs -- the costs incurred to be able to make a part -- and per-unit costs -- the costs required to make one additional part. Casting and Injection molding are excellent examples of high overhead/low per unit costs -- at low volumes, the distributed cost of the molds required drive the part cost up to unreasonable levels. However, since the added cost per-unit is extremely low, the overall part cost becomes very cheap at high volumes. Their cost/volume curve looks like this:

In virtually every manufacturing method, cost per part drops significantly as part volume increases.

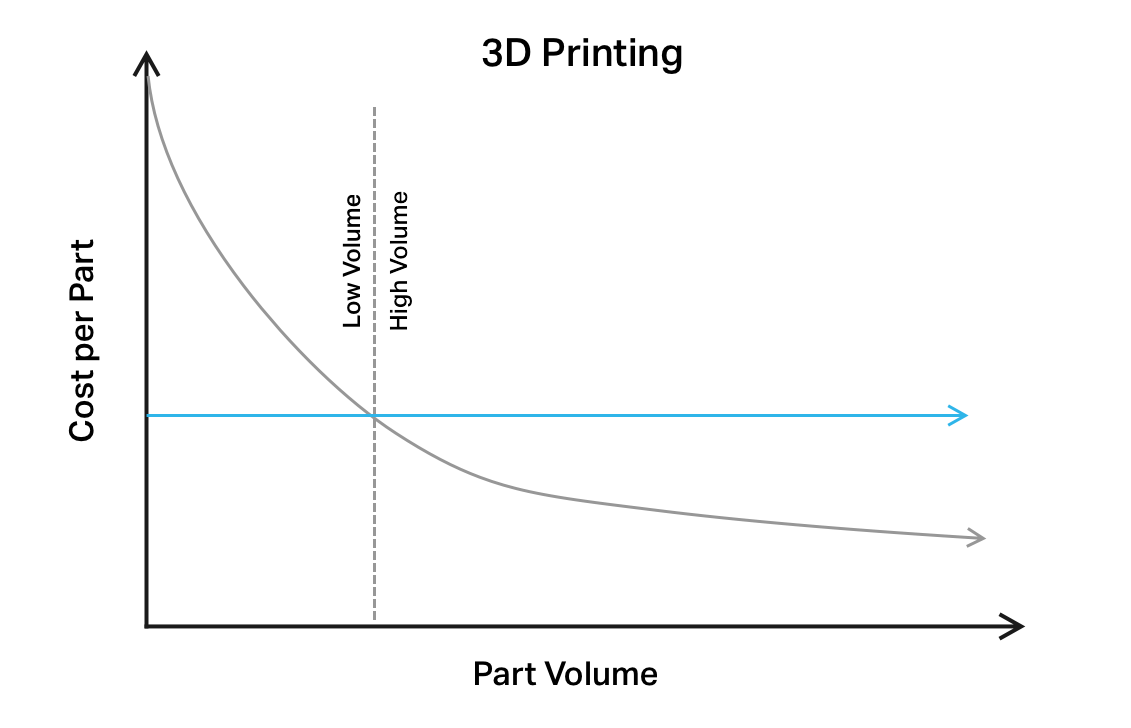

Metal 3D Printing subverts this by utilizing a largely automated process that incurs almost no overhead costs. There’s minimal extra upfront labor in printing the first part over the 100th, and the system uses the same amount of consumables (for the Markforged Metal X this is filament, washing fluid, and sintering furnace gas) on every part. This locks part cost regardless of part quantity and a cost graph that looks like this:

3D printing has a stable cost per part and is not dependent on print volume. As a result, it can be the most economical way to product low volume parts.

Metal 3D printing isn’t the most cost effective manufacturing method for all volumes -- at high volumes, most other manufacturing processes are significantly more affordable. However, for a significant slice of low to medium volume production, metal 3D printing can be the most affordable way to make parts.

In metal 3D printing, complexity is free

Years of design for manufacturing training have left most engineers hard coded to design parts that are as simple to fabricate as possible. The justification behind this is as simple as it is economical: for the vast majority of fabrication processes, added complexity equals added cost. Complex parts require more work to program machines, more advanced machines to do the fabrication, and take more time to complete. Across most fabrication methods, this stays remarkably consistent; everything from mills to cast parts are affected. Metal 3D printing is not.

Nearly all metal fabrication processes rely on a subtractive process (even casting needs molds). Conventionally manufactured parts all begin as a block of metal, with the machine (usually a mill or something similar) removing material to create the final part. For complex parts, these operations can be both extremely difficult and time consuming to perform. The result is expensive parts that take a long time to fabricate and waste significant material.

Complex parts like these impellers are incredibly expensive to machine, but quite affordable to print.

Due to a largely automated additive process, metal 3D printing costs are driven by part size instead of complexity. Tool pathing is done by 3D printing slicing software, eliminating the labor and CAM costs native to conventional methods. With no programming and only small preparation responsibilities, part cost is only the material and maintenance of the machine. The additive process yields little wasted material and movement in the fabrication of a part. If a design is printable, complexity doesn’t cost extra.

3D Printers can make parts no other machine can

Every fabrication method has limits -- 3D printing is no exception. However, due to its unique process, metal 3D printing is capable of fabricating parts that cannot be made with any other platform. The result is parts that can be truly optimized for their use case rather than limited by traditional manufacturing constraints. These parts range from ultra complex -- like topology optimized parts from generative design software -- to process optimized -- like injection molds with conformal cooling channels or custom manifold design. Most of these “impossible parts” have one key feature in common: complex curves, shapes, or cavities where conventional processes simply can’t remove material.

The ability to print curved cavities allowed Stanley Black & Decker engineers to consolidate a four part assembly into a single 3D printed part.

The breadth of impossible parts that can be fabricated on metal 3D printers have not been fully explored yet, so applications are not fully known. As metal 3D printing is adopted by the manufacturing masses, we’ll likely see new design paradigms centered around the unique strengths of 3D printing as a process. Metal 3D printing is by no means the singular future of manufacturing -- however, it presents an alternate method of manufacturing that opens up new opportunities that were previous cost or design prohibitive. Metal 3D printing will become an invaluable tool for engineers, designers, and fabricators everywhere.

Thanks for checking out the EXBuild blog! Make sure to subscribe down below to have more 3D Printing and Additive Manufacturing content like this delivered straight to your inbox!

Written by Markforged

Markforged is transforming manufacturing by addressing 3D printing as a holistic problem. Their process innovations are only possible by a combined effort in advanced cloud computing, cutting-edge materials science, and industrial design.