When 3D printing first arose, the imagination of users and producers alike militated against real-world use. Now expectations have slowed down as the technology has sped up to meet in the middle. There are $1,000 printers today that compare favorably to the $50,000 printers of a decade ago.

To maximize the potential of 3D printing, however, users still need to understand how the home hobby maker and the fablab-level printers compare.

Among the several differentiators are two important ones: time and money.

TIME

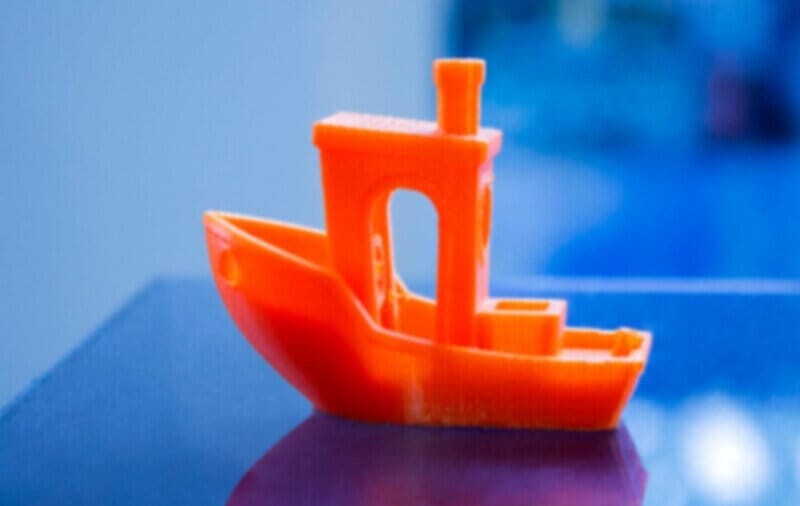

With a hobbyist machine these days, it will feel like you have infinite options for filament, software, and hardware upgrades. Home 3D printers are great for printing a few items such as Benchies or Baby Yodas, but those printers have some drawbacks. Home 3D printers can be difficult to use. You may find yourself reprinting once, twice, three or four times to get it right. Some may find satisfaction in finally getting the perfect print, others may not, but that’s exactly why these printers are perfect for hobbyist applications — they take extra time. Hobbyist users are looking for an activity, a way to spend time.

Conversely, professional 3D printers are built for efficiency, built to save time. With a home 3D printer, spending time is the goal. For a professional printer, time costs money.

MONEY

If you are in a position to decide between a hobby machine for as low as $200 and a $20,000 professional machine, there is a way in which paying more costs less.

One example is the Markforged Mark Two. This machine enables designers and engineers to replace machined aluminum tooling with stronger parts for a fraction of the price. It combines unique continuous carbon fiber reinforcement and distinctive software with industrial 3D printing, for versatile parts that are ready for immediate use, with up to 26 times the strength of standard 3D printing materials like ABS.

It's not just the materials that save money. It’s also the fact that well-built, stronger products cost less because they need to be replaced less frequently.

But don't just take our word for it. Learn how companies like RPG Industries save both time and money using the full range of Markforged printers throughout their production process.

Where can Markforged fit into your production process?

Written by Markforged

Markforged is transforming manufacturing by addressing 3D printing as a holistic problem. Their process innovations are only possible by a combined effort in advanced cloud computing, cutting-edge materials science, and industrial design.