Up until now, 3D printing very large parts has been costly, slow, and problematic. Large format 3D printers, their software, maintenance, and consumables are all extremely expensive and the finish can still be rough requiring a lot of post-processing. One option can be to use more affordable small printers to print in smaller pieces and then carefully join them together, but its more time consuming and the part may not fit together properly. Either way, the process is slow and parts could fail during the print or worse, later in use.

The launch of Photocentric’s Liquid Crystal Titan 3D printer (LC Titan), the largest LCD printer ever made, opens a new opportunity for printing very large objects at high resolution, reliably, and also cost effectively. This will be of interest to a wide range of companies who want to manufacture large objects inhouse.

These eleven tips show the key variables to control to achieve reliability, resolution, part accuracy, build speed and affordability when printing very large objects.

1: Use free radical, not cationic cured resin

On the face of it, this seems counter-intuitive to use free radical as all large laser systems use cationic ring opening epoxy systems to cure large objects, as the shrinkage in ring opening is inherently less in comparison to double bond breaking. However, with astute formulating it is possible to mitigate the shrinkage in free radical systems, and they then offer some amazing benefits over cationic systems. Polymerization is considerably faster, and when producing large objects, this makes a huge difference in the utilization of the expensive equipment making it an order of magnitude more productive. Free radical polymerization produces irreversible, strong chemical bonds that are amongst the most long lasting in nature, so the parts can be functional. The variety of properties available is much wider in free radical polymerization, encompassing everything from hard to elastomeric.

Large Format 3D Printer – Liquid Crystal Titan the largest LCD 3D printer

2: Print on a large-format resin printer

SLA (Stereolithography apparatus) or resin printing is the only method that can deliver all the requirements of large scale, fine feature resolution, low cost and functional strength. Recent developments in LCD resolutions have increased the resolutions achievable to deliver high definition in large scale. Coupled with advancements in the back lights illuminating them, they are now setting the standard in the delivered appearance of large, printed parts.

Titan’s build volume of 695 x 385 x 1200 mm (27.3 x 15.2 x 47.2″) is more remarkable in that it has a pixel pitch of just 91 microns across the entire area. It delivers phenomenal final part resolution across a very large area, creating amazing looking, but also very large parts.

Explore Liquid Crystal Titan >

3: Print with daylight rather than UV

When printing with LCD, conventional wisdom may suggest that UV (405nm) would be faster to initiate polymerization as it transfers more energy proportionately than visible light (460 nm). However, visible light (often called daylight) cures more consistently across a large surface area delivering more controlled double bond conversion. This allows uniform and simultaneous curing across the build area and gives more consistent cure depth regardless of intensity variations.

Daylight curing creates higher quality parts without damaging the LCD screen from UV degradation, which in time would become source of poor-quality printed parts. Photocentric have printed more than 5 million objects with daylight, and it is the proven choice for continuously operated digital mass manufacturing processes.

4: Design the part to counter shrinkage and eliminate warpage

All printing processes shrink, but large parts shrink in absolute terms the most. The key is understanding how shrinkage affects the structures and then to prevent them from being able to distort the final shape. The right software will orientate and support the part so that the structure doesn’t delaminate when peeling takes place. The forces need to be evenly mitigated across a dense matrix of the support network to ensure print reliability.

Warpage can be prevented by adopting Photocentric’s ‘Weave’ process, a software and design system that reliably prints large parts, even creating very large level and flat surfaces. The Weave process assesses the necessary the physical strength that the part should have when subjected to forces in different directions and then designs to meet those criteria, whilst simultaneously optimizing it to reduce its weight. It uses techniques such as latticing the solid parts to reduce mass and avoid warpage. The lattice structure will pull in on itself to remain isotopically constant. Printed objects will also then consist of only the necessary material to deliver the strength required.

5: Print cost-effectively

You must perform a total cost of ownership (TCO) on the entire process, not just the weight of the resin, to evaluate the real cost of making large parts. Some 3D printer companies further monetize their sale by using expensive maintenance contracts, software licenses with eye-wateringly expensive renewals, costly spare parts (particularly with lasers) and consider technician visits as revenue generators.

Photocentric provide a TCO on the parts made on Titan, it is the critical number a customer needs to know. It should be possible to take an exemplar part and get the TCO for it when using competitive machines. LCD has the lowest electricity usage of all 3D printing processes and if the resin is reclaimed, generates the lowest carbon footprint. Titan uses daylight, rather than UV, and as such the screen will last forever. Photocentric manufacture the hardware, consumables and use them to make parts, so they understand how important it is to make the TCO as low as possible.

6: Print bottom-up, rather than top-down

It seems intuitively logical that when printing very large objects with resin, top-down would work the best. Gravitational forces act in favor of the print as the part lowers into the vat with the liquid supporting the growing structure and there are no peeling forces to deal with. However, if you overcome these problems then the advantages of printing bottom-up much more significant. There is no very expensive vat of resin that will become unstable, no problem changing over resin grades, the parts and platform drip dry during printing and the platform is easily movable onto the wash section.

Titan works with bottom-up printing using resins with high green strength and low shrinkage and the inbuilt blow peel mechanism that lifts the part from the vat with the platform, removing peel forces. Titan’s massive build would require a third of a ton of resin to be purchased and loaded just to start printing a part in a top-down configuration. Instead, Titan works with a consistent 5kg of resin in the vat. The platform and part are largely dry at the end of the printing process, reducing wash contamination and making it easier to lift out and place in the wash via the purpose made transfer unit.

7: Use the right post processing techniques and recycle the resin cleaner

Your problems may only just be starting when you look at your perfect print hanging on the platform, as post processing large objects is technically much more challenging than in desktop size. To be successful and reduce your waste you must have a proven workflow solution in place with on-platform wash and cure processes. Removing parts before processing may make handling simpler, but in free radical systems it won’t retain the isotropy of the parts. To achieve this, you must post expose completely on the platform. It is impractical to have large tanks filled with wash liquid because twice the print height is required to allow the platform to lift clear. For this reason, cleaning is more effectively performed with directional jets of resin cleaner. Curing large parts is also more problematic to smaller ones, as the curing must be performed evenly on all surfaces to prevent one face shrinking non-isotopically. Large format 3D printing produces a lot of waste resin cleaner that will have to be collected, this has to be dealt with effectively. The environmentally correct thing to do is now also the financially sensible thing to do, and saturated resin should be reclaimed.

Photocentric supplies dedicated purpose-built wash and cure units. The Titan wash is designed specifically to allow manual direction of the jets into concealed areas and the Titan cure unit delivers the necessary heat and light consistently with the platform rotating to deliver create even cure. Photocentric’s resin cleaner is safe to use and non-flammable, and can also be recycled endlessly with their designated resin reclaim unit. This provides a rapid payback and creates material that can be solidified in sunlight for land fill or burning, and also resin cleaner that can be reused.

8: Cure the entire build area simultaneously

SLA (Stereolithography apparatus) or resin printing with light, is the only method that will deliver large format prints with functional strength and fine feature resolution. LCD is the only SLA method that will provide these advantages and do it rapidly. This is because LCD screens cure large areas simultaneously, whereas other methods cure very small areas or even just pixels, sequentially.

The 8k (7660 x 4320 pixels) LCD screen in Titan places the user in control of over 33 million pixels all switchable simultaneously. This allows the user to convert huge amounts of liquid into solid in a short time and is an order of magnitude more capacious than using lasers.

9: Print with optimized settings

Printing bottom-up is undoubtedly simpler and more cost-effective than top-down, but it is also much less forgiving. It requires both optimization of the process and settings. It is imperative to overcome the peel and gravitational forces as the large part hangs in space and worse must pull away from the vat film. For this to work, every time, through thousands of layers, the print process must operate within wide operational margins. The exposure latitude must be wide enough to enough polymerization, without over-exposure, given reasonable variability in temperature. The delay and lift speed must be set to ensure forces and liquid flow are all but eliminated. The addition of resin must be automatically controlled to allow only the polymerized resin to be replaced. The enhanced peel system by vat lifting or declining, blowing in under the vat.

Photocentric have circumvented the forces during lift in bottom-up printing by using their patented Blow-Peel technology which inflates air under the vat just before the platform lifts. This changes the angle the part peels away from the vat film, enabling faster disengagement of the print from the film with lower force thus delivering consistent printing. Photocentric has 9 years of experience in large format 3D printing that have led them to the optimized print settings used in Titan, delivering performance without compromising on reliability or quality.

10: Use resins with high green strength and adequate depth of penetration

Green strength, or the strength of the part at the time of printing, as opposed to its final post exposed strength, is the vital criterion for successful large format 3D printing. Large parts require a high threshold of initial strength to stay in place during creation. Too low a green strength and the part will simply pull apart and delaminate along its layers. Large parts benefit from being able to print with a greater depth of cure, as the print time can be reduced substantially by using thicker layers. When curing a very large object in very small slices, you want it done quickly. Correspondingly, the part must look great afterwards, meaning no ugly layer lines that need lots of sanding or polishing.

To enable reliable large format 3D printing, Photocentric have designed resins that have very high green strength and make attractive looking parts that can look indistinguishable from molded parts. Photocentric recommend Magna Hard Black (for prototyping) and Durable DL110HB (for toughness) in Titan. Typically, 100 microns is the thinnest layer used in large format 3D printing, but Titan will deliver very high resolution, amazing looking parts at 250 and even 350 micron layers.

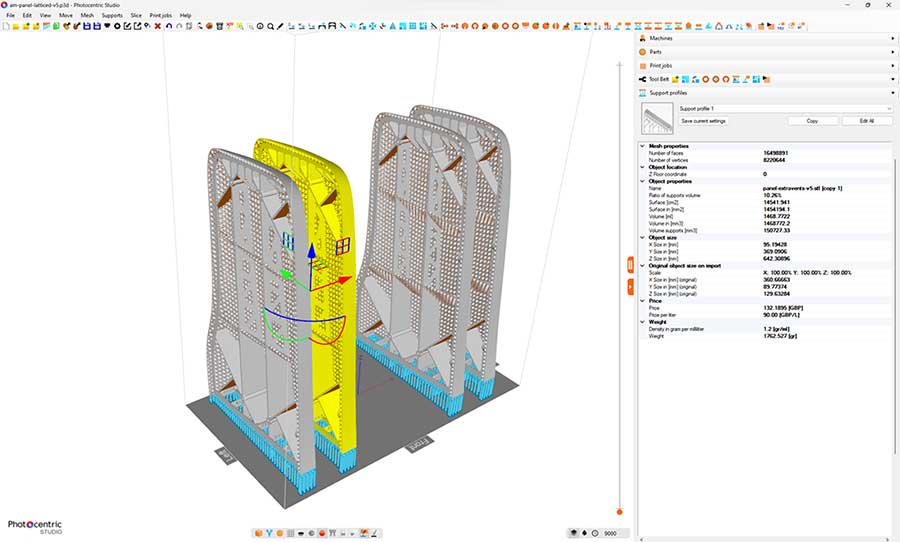

11: Use the correct support and hollowing software

Failure when printing large parts is much more costly than in smaller format. The consequences of getting to the end of print that took a day or more to find a failure in it are profound in missing deadlines and reorganizing schedules. A major part of achieving repeated success is the use of the right software. It must hollow the part as much as possible to reduce cost and weight, latticing where possible to again make it lighter, stronger and shrink less. It must apply vent holes to prevent cupping and of course to create a network of support structures to allow unsupported parts to be built and to retain isotropy during peeling. Manually supporting a large part can be very time consuming, but an auto-support feature must be able to understand how the surfaces relate to each other. It must be able to produce fine support tips to prevent excess post processing, but with a strong inter-connected network of branches that at the same time doesn’t waste a lot of resin.

To coincide with the launch of Titan, Photocentric have created an upgraded version of their Studio 3D printing software that enables large parts to be automatically supported in the optimal manner with very fine support tips and strong inter-connected lattice of supports. It also has the ability to import any predesigned lattice structure in addition to its programmed library.

Written by The EXBuild Team

The EXBuild Team of application engineers combined their depth of experience and industry knowledge to bring you the contents of this article.