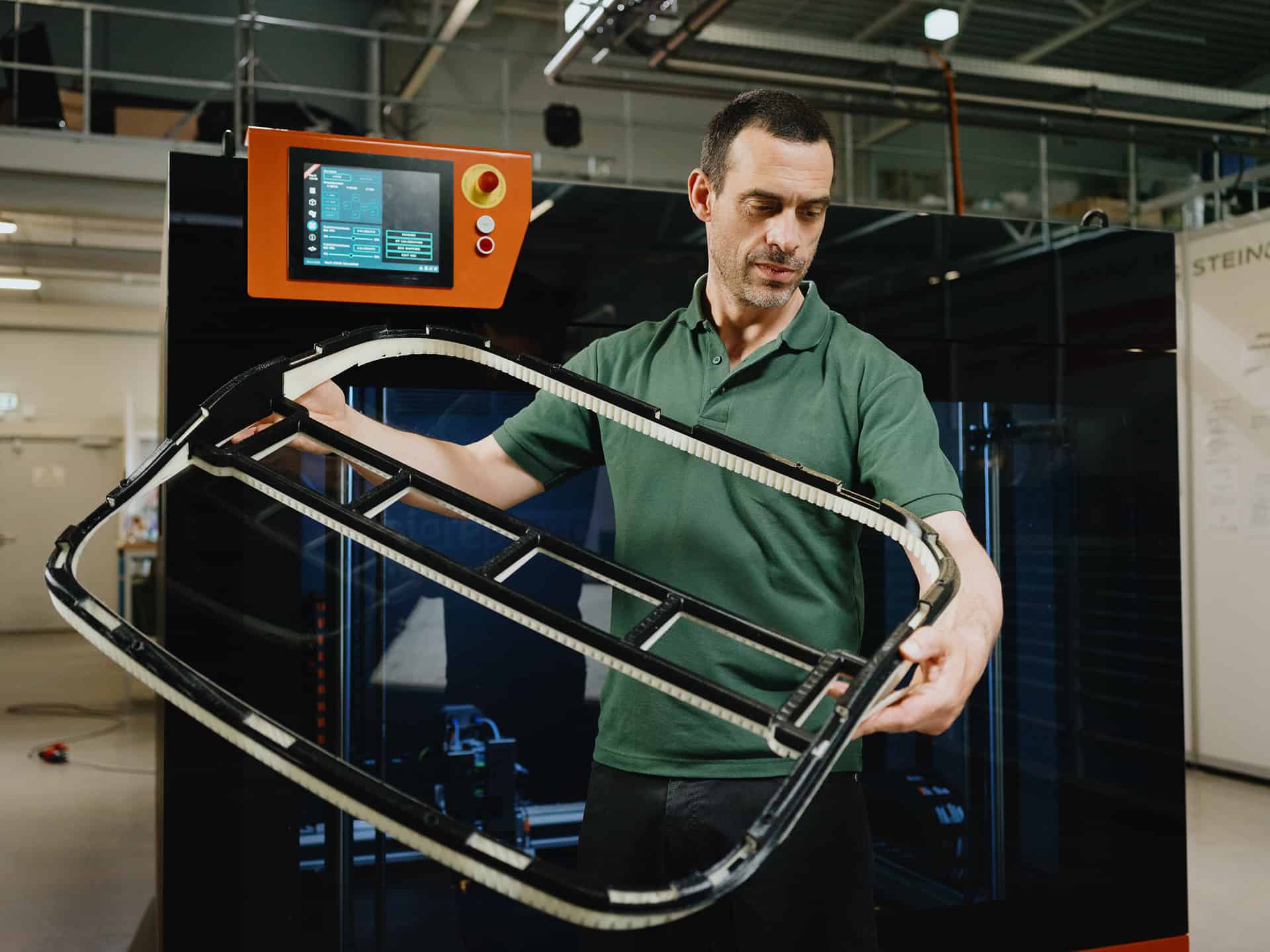

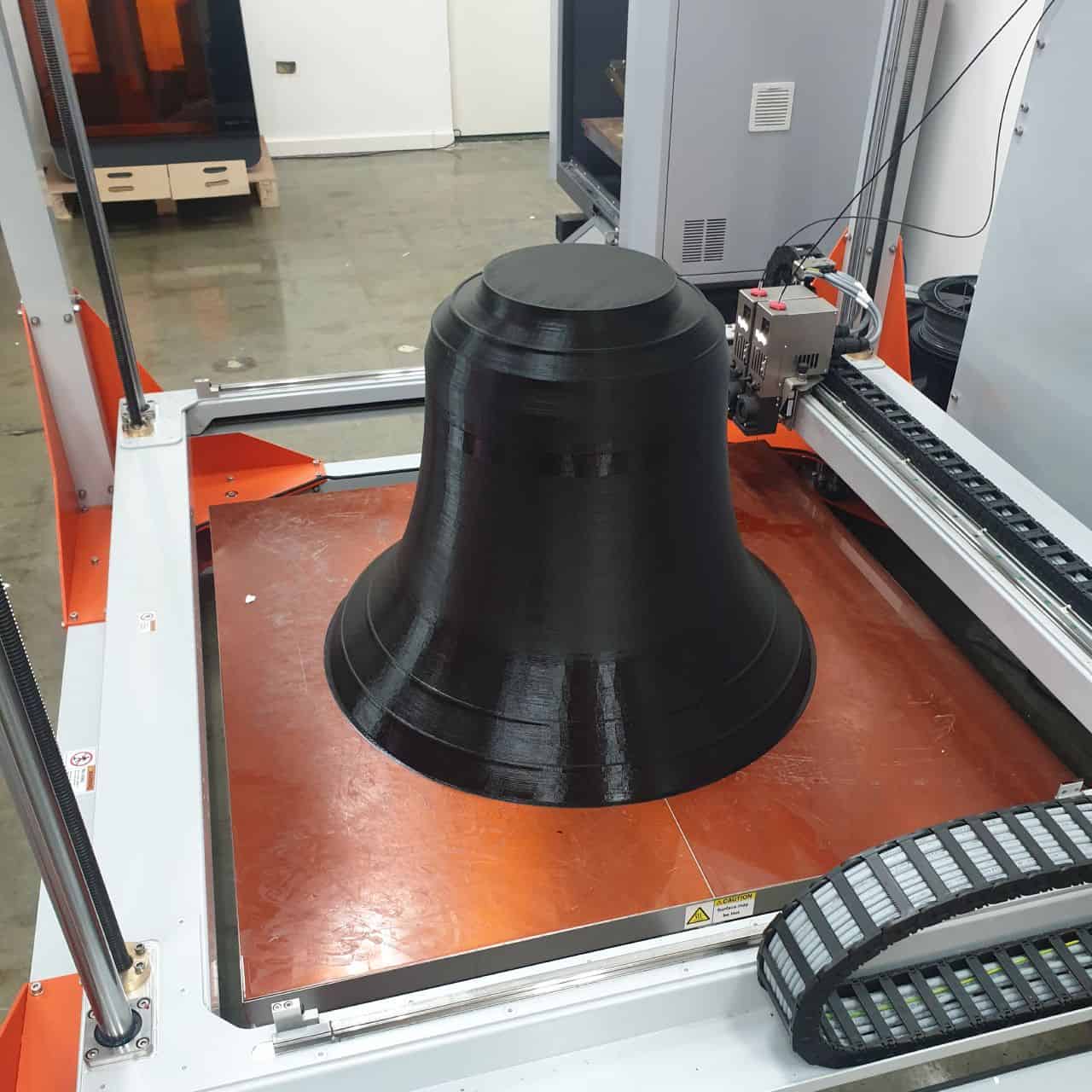

I’m excited to introduce our newest material to the Markforged platform and to the rest of the manufacturing world — Smooth TPU 95A! This material brings an entirely new set of functional properties to the Digital Forge and adds a substantial amount of versatility to what’s possible with Markforged 3D printers.